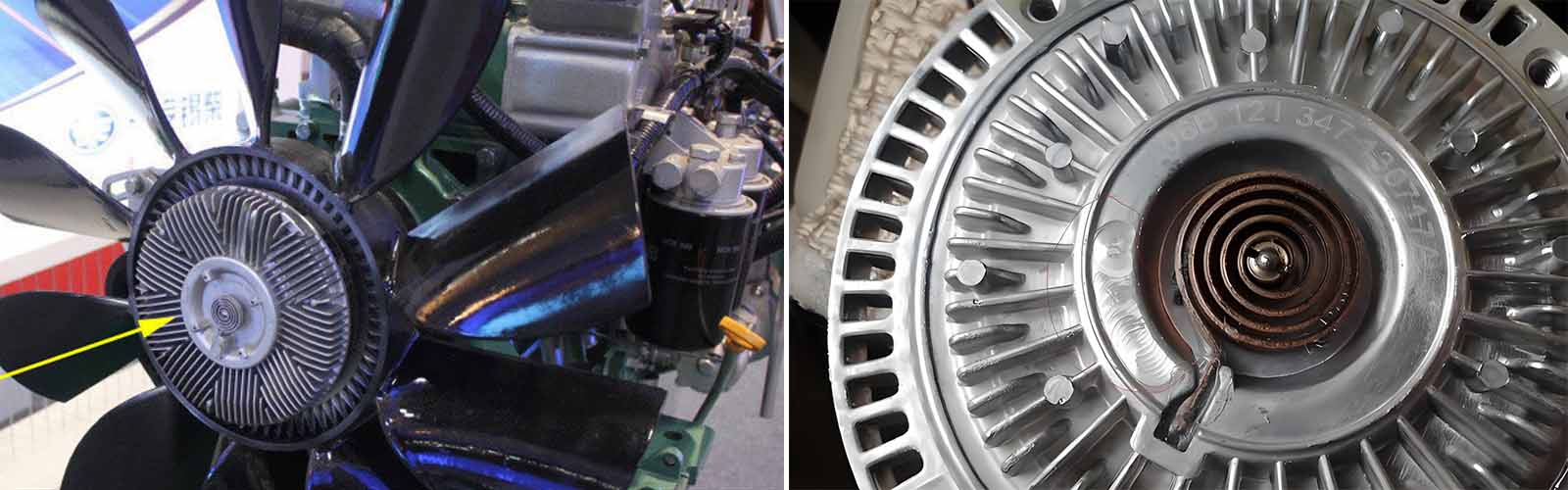

Silicone oil is a viscous fluid. A cooling fan with silicone oil is called a silicone oil fan and is usually used as a medium in automobile cooling fan clutch components. It is also used in newer electronic fan clutches to control cooling fan speed. For example, the advanced electronic silicone oil clutch fan can achieve more precise temperatures to meet the automotive requirements for air volume and noise changes. In the automobile cooling system, viscous silicone oil is used to transmit torque to realize the separation and coupling of the fan clutch, and can also transfer heat to the front cover of the heat sink and the clutch housing. using silicone oil's clutch reduces fan power consumption, decreases noise and wear, and can also prevent the engine from being overcooled, and can also prevent the engine from being overcooled, thereby reducing pollution and saving fuel. Silicone oil clutches are very suitable for application in vans, semi-trailers, trucks, and hard-core off-road vehicles that require the reliability and stability of cooling fans.

Characteristics of silicone oil

Small viscosity changes over a wide temperature range (-50°C to +250°C)

It has good thermal stability for high-temperature and sealed environments.

It has excellent shear resistance, more than 20 times that of petroleum oils.

It can withstand extreme pressures without solidification and exhibits very high compressibility.

How does silicone oil realize the separation and combination of the clutch fan?

When the engine load increases, the temperature of the air flowing through the radiator rises. The bimetal thermometer is blown by the high-temperature airflow and deformed by heat, causing the valve plate to rotate away from the oil hole and open the oil inlet hole on the driven plate. The high-viscosity silicone oil stored between the driven plate and the front cover enters the working cavity between the driving plate and the driven plate, causing the clutch to combine and drive the housing and the fan to rotate. The size of the oil inlet hole and the fan speed depend on changes in air flow temperature.

The air temperature drops due to engine load reduction or other reasons. The bimetallic piece receives less heat and returns to its original shape, forcing the valve piece to rotate and close the oil inlet hole. The remaining silicone oil in the working cavity flows back into the oil storage chamber due to centrifugal force during the rotation process until it is empty. At this moment, the clutch is separated, the active plate returns to an idling state, and the fan speed becomes very low.

What are the benefits of using silicone oil for clutch fans?

The clutch using silicone oil accurately controls the fan speed, allowing the automobile engine to always operate at the optimal operating temperature, avoiding wasted operation at low temperatures, improving the working efficiency of the car engine, and reducing engine wear.

Even if the engine is running at low speed, the cooling system temperature can be accurately controlled to prevent the fan from forcing heat dissipation and causing the engine temperature to be too low.

The silicone oil clutch fan can adjust the fan speed according to actual needs, reducing energy consumption and noise pollution.

Electronic clutches using silicone oil provide more precise and faster response.

Silicone oil with high viscosity characteristics makes the fan speed more stable.

As a cooling system, silicone oil clutch fans play a vital role in the working efficiency of heavy-duty truck engines. Compared with ordinary clutches, fan clutches using silicone oil can automatically adjust the cooling intensity of the engine, reduce the waste of engine power consumption, and also meet the requirements of reducing Noise pollution and exhaust emissions requirements. Yongrui's silicone oil has cut-off resistance, lubrication, and shock-proof functions, with a viscosity of 5-12500cst, and is suitable for automotive electronic control systems.